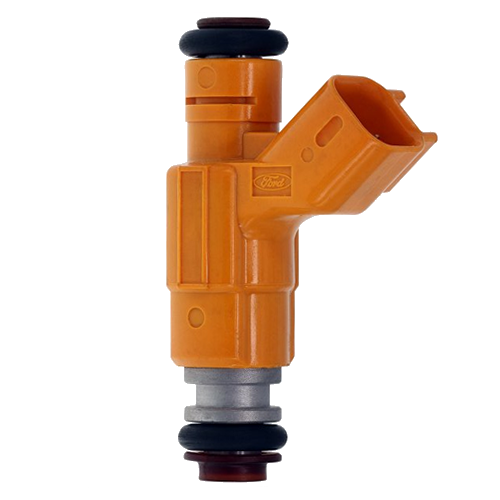

Looking for dependability? Our Remanufactured Fuel Injectors exceed OE standards because they’re Remanufactured using Advanced Remanufactured Technologies surpassing OEM processes. Our Remanufactured Fuel Injectors are built with the most extreme climate, and harshest conditions in mind. Whether it be Extreme Cold, Hot, Dirty or Wet, Python Fuel Injectors have been remanufactured to withstand the test of time. Purchase and install with confidence once and keep on driving!

How Rotex Remanufactures Fuel Injectors

- All remanufacturing including, coil winding, CNC machining, plastic injection molding, fuel injector assembly, testing and boxing completed in our large state of the art factory in Gardena, California.

- All O-Rings, bushings and spacers are 100% NEW.

- A fine-mesh strainer is used to protect against fuel contaminants.

- Electromagnetic Coil is encased in Kapton or molded to protect against electrical leaching.

- Pintle and Pintle Seats are matched and blueprinted to increase the fuel flow rate and atomization cycle.

- All flow rates exceed OEM specifications.

- Spray pattern is examined at varying engine speeds to assure optimum fuel atomization.

- Leak testing at three times the required operating pressure

- Flow rate precisely metered to the appropriate pulse width to within 2% of OEM specifications.

100% Remanufactured Fuel Injectors

Demand Reliability – Python Fuel Injectors are designed for customers who demand reliability and performance. Our Fuel Injectors are remanufactured to exceed OE standards.

Demand Performance – Faulty units can add costs, risk, time and customer dissatisfaction to the repair job. Every Fuel Injector is tested prior to departing the factory using our State-of-The-Art test equipment. These tests ensure all units exceeds OE quality specifications.

Demand Form Fit and Function – Python Fuel Injectors are built to exceed OE Form, Fit and Function specifications.

Demand Service – Our customer service provides customers with the tools to complete the job quickly and efficiently. We offer services such as specialized catalogs, unit images, technical bulletins, installation and troubleshooting tips and more.